Experimental and simulation study of direct current resistance

Oct 10, 2023 · Understanding the contribution of internal direct current resistance (DCR) is crucial to the design and optimization of lithium-ion batteries (LIBs). However, the complex dynamic

Regulating charge heterogeneity of lithium-ion battery via

Oct 1, 2023 · Construction of high-throughput electrical transmission structure via tab design is an effective way of developing high-power lithium-ion batteries (LIBs). In this paper, five types of

Mitigation of cylindrical lithium ion battery thermal runaway

Feb 1, 2025 · Ensuring fire safety in Lithium ion battery (LIB) thermal runaway propagation (TRP) is a key challenge in electric vehicle battery pack design. A seri

Room-temperature cylindrical lithium battery enabled by

Jun 1, 2025 · However, the practical application of cylindrical batteries is hindered by their high operational temperatures (above 240 °C). Herein, we report a sulfide-based cylindrical battery

Low temperature heating methods for lithium-ion batteries:

May 1, 2025 · However, such researches generally entail long industrialization cycles. On the contrary, the heating methods for power batteries are more suitable solution in the short term.

Cylindrical Lithium Technologies

5 days ago · High Energy Formula contributes to Cylindrical Lithium''s long-lasting endurance in mid- and high-drain applications, such as cameras, where the

Determination of Internal Temperature Differences for

The temperature of lithium-ion batteries is crucial in terms of performance, aging, and safety. The internal temperature, which is complicated to measure with conventional temperature sensors,

How to enable large format 4680 cylindrical lithium-ion batteries

Nov 1, 2023 · The demand for large format lithium-ion batteries is increasing, because they can be integrated and controlled easier at a system level. However, increasing the size leads to

Thermal management study of cylindrical battery using

As high density electronic-energy units, cylindrical lithium-ion batteries face significant thermal runaway risks. To address this concern, we develop

Comprehensive electro-thermal model of 26650 lithium battery

Apr 1, 2020 · Ambient temperature affects the electro-thermal performance of lithium iron phosphate (LiFePO4) batteries in electric vehicles. This paper proposes a

Determination of Internal Temperature Differences for

Feb 6, 2024 · This study presents a method in the time domain, based on the pulse resistance, for determining the internal cell temperature by examining the temperature behavior for the

Investigation on Thermal Characteristics and Performance of Cylindrical

May 14, 2024 · Efficient heat dissipation in lithium-ion battery packs is crucial for safety, necessitating a thorough assessment of thermal performance during the design phase. This

Internal temperature prediction model of the cylindrical lithium

Jul 25, 2022 · Herein, a prediction model for cylindrical 18,650 lithium-ion batteries is established to reveal the internal temperature under various boundary conditions. Firstly, T-type

Design, Properties, and Manufacturing of

Jun 3, 2023 · This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim

Temperature effect and thermal impact in lithium-ion batteries

Dec 1, 2018 · As rechargeable batteries, lithium-ion batteries serve as power sources in various application systems. Temperature, as a critical factor, significantly impacts on the performance

Determination of Internal Temperature

Jun 23, 2022 · Determination of Internal Temperature Differences for Various Cylindrical Lithium-Ion Batteries Using a Pulse Resistance Approach

Investigation of novel type of cylindrical lithium-ion battery

Sep 30, 2024 · The in-depth research on the heat exchanger for lithium-ion batteries is of significant importance due to its crucial role in ensuring the safe operat

Study on the battery thermal management system for cylindrical lithium

The operating range of lithium-ion batteries is 25–40 °C, and the temperature difference between the cells in the battery pack should be less than 5 °C 4 – 6. If the temperature of the batteries

In-situ temperature monitoring of a lithium-ion battery

Oct 1, 2022 · Uncertainty in the measurement of key battery internal states, such as temperature, impacts our understanding of battery performance, degradation and safety and underpins

Thermal Characterization of a Cylindrical Li-ion Battery Cell

Dec 14, 2020 · Abstract The operating temperature of Li ion batteries is one of the main aspects to consider when analysing the battery''s performance. The battery''s internal temperature in

Improved equivalent circuit coupled 3D thermal cylindrical lithium

Jun 15, 2024 · This study introduces an improved equivalent circuit coupled 3D thermal model, the Multi-Partition Heat Generation and Thermal Resistance (MPH-TR) Model, developed for

Size effect on the thermal and mechanical performance of cylindrical

Dec 1, 2024 · Abstract Increasing the size of cylindrical lithium-ion batteries (LIBs) to achieve higher energy densities and faster charging represents one effective tactics in nowadays

Investigating thermal dynamics in cylindrical Li-ion

4 days ago · Thermal dynamics in cylindrical Li-ion batteries, governed by electrochemical heat generation, are critical to performance and safety in high-power applications such as electric

18650 vs. 21700 Li-ion cells

Oct 1, 2020 · Li-ion cells of the classic 18650 format are directly compared with the new 21700 format regarding electrochemical, thermal, and geometrical propertie

Measurement of thermophysical parameters and thermal

Aug 15, 2023 · Cylindrical lithium-ion batteries are widely used due to the advantages of high performance and stable uniformity [1]. When the battery is operating, self-generated heat

Comparative analysis of cylindrical lithium-ion battery

Aug 1, 2025 · With the widespread application of electric vehicles, energy storage systems, and portable electronic devices, lithium-ion batteries, particularly cylindrical cells, have become a

Base vs Side Cooling Cylindrical Cells

May 21, 2023 · Base vs side cooling of cylindrical cells is often brought up in online discussions and in many OEMs designing battery packs.

Thermal Characterization of a Cylindrical Li-ion Battery Cell

Dec 14, 2020 · The operating temperature of Li ion batteries is one of the main aspects to consider when analysing the battery''s performance. The battery''s internal temperature in

Direct measurement of internal temperatures of

Sep 2, 2023 · Direct access to internal temperature readings in lithium-ion batteries provides the opportunity to infer physical information to study the effects of increased heating, degradation,

Thermal management of cylindrical lithium-ion batteries

Jul 15, 2025 · Effective BTMS is essential to keep LIBs in their optimal operating temperature range. Efficient thermal management methods are required because research has shown that

An investigation on electrical and thermal characteristics of

Jun 15, 2021 · Abstract. Lithium-ion batteries suffer severe performance degradation and exhibit highly nonlinear characteristics under low-temperature environments. Determining the

Degradation behavior of 21700 cylindrical lithium-ion battery

Nov 30, 2023 · Abstract Lithium-ion battery (LIB) cells are prone to overdischarge or overcharge when connected in series or parallel as a module or pack for large-format applications, such

Prognostic analysis of thermal interface material effects on

Nov 30, 2023 · Experimental measurements of direct current internal resistance, temperature-dependent open circuit potential, and electrochemical impedance were conducted to obtain

Characterizing and predicting 21700 NMC lithium-ion battery

Jun 5, 2022 · Combined numerical and experimental studies are conducted to characterise 21,700 cylindrical lithium-ion battery (LIB) thermal runaway (TR) induced by nail penetration.

An online temperature estimation for cylindrical lithium-ion batteries

Nov 1, 2022 · Accurate modeling of electrical-thermal properties is essential for safe use and efficient and reliable thermal management of Lithium-ion batteries. However, online estimation

Comparison on Thermal Runaway and Critical

Nov 15, 2024 · This review on the critical characteristics of cylindrical batteries under thermal failure and thermal abuse provides a reference for solving intrinsic safety issues for lithium-ion

Thermal Conduction in a Cell

Jun 28, 2022 · Whatever way we cool a battery cell we will create temperature gradients in the cell. It is not possible to apply cooling to all of the active area

Thermal Investigation of Cylindrical Lithium-ion Batteries for

Dec 8, 2022 · Thermal investigation of cylindrical lithium-ion batteries of different chemistry and shape factors (18650 NMC and 21700 NCA) is conducted for different charging/discharging

6 FAQs about [Cylindrical lithium battery temperature resistance]

Do cylindrical lithium-ion batteries have a thermal stability problem?

This work is motivated by the critical need to improve the thermal stability of cylindrical lithium-ion batteries, especially in electric vehicles and high-performance electronics, where overheating during rapid charging and high discharge rates can lead to thermal runaway and decreased lifespan.

What is the thermal investigation of cylindrical lithium-ion batteries?

Thermal investigation of cylindrical lithium-ion batteries of different chemistry and shape factors (18650 NMC and 21700 NCA) is conducted for different charging/discharging rates (0.5 C, 1 C, 1.5 C) and surrounding temperatures (26 °C and 45 °C) using numerical and experimental techniques.

Does PCM improve surface temperature in lithium-ion batteries?

Comparative analysis of surface temperature in lithium-ion batteries: with and without PCM thermal management at 2C and 3C The principal mechanism underlying this enhanced thermal performance is PCM’s inherent capacity to absorb significant amounts of heat generated during high discharge rates.

Do lithium-ion batteries need thermal management?

The rapid growth of electric vehicles (EVs) and portable electronic devices has intensified the need for efficient thermal management in lithium-ion batteries (LIBs), prone to overheating and catastrophic failure if not adequately managed.

Why are cylindrical lithium-ion batteries used in electric vehicles?

This study is particularly significant because cylindrical lithium-ion batteries are widely used in electric vehicles due to their high energy density and mechanical robustness. Various fin configurations are analyzed to optimize heat dissipation, effectively reducing peak temperatures during high discharge operations.

Are 18650 NMC and 21700 NCA cylindrical lithium-ion batteries thermally investigated?

In this research work, thermal investigations of 18650 NMC and 21700 NCA cylindrical lithium-ion batteries have been carried out for different charging/discharging rates and surrounding temperatures using numerical and experimental techniques.

Industry Information

- Tskhinvali 299A high frequency inverter

- Industrial flywheel energy storage power supply

- High quality solar power storage batteries for sale

- Types of outdoor base stations

- What are the outdoor energy storage power supplies in Jakarta

- Assembly of outdoor battery inverter

- Huawei Burundi Energy Storage Photovoltaic Products

- Vertical axis wind-solar hybrid power supply system

- Container generator set 1000kw

- Portable power source factory in Ukraine

- Is the energy storage power station the most recommended

- New concentrated solar photovoltaic panels

- Maseru Energy Storage Photovoltaic Water Pump

- Huawei s 10 billion energy storage system project

- On grid hybrid solar inverter in Canberra

- Brazzaville multifunctional energy storage power supply price

- Belmopan Long-Term Communications Base Station Uninterrupted Power Supply

- Temporary mobile power supply level 3 power box on construction site

- Valletta communication base station inverter grid-connected equipment customization

- Onsite Energy Outdoor Solar Power

- Canberra local energy storage battery merchants

- Sunshine inverter price 80kw

- Marshall Islands Energy Storage Power Generation

Commercial & Industrial Solar Storage Market Growth

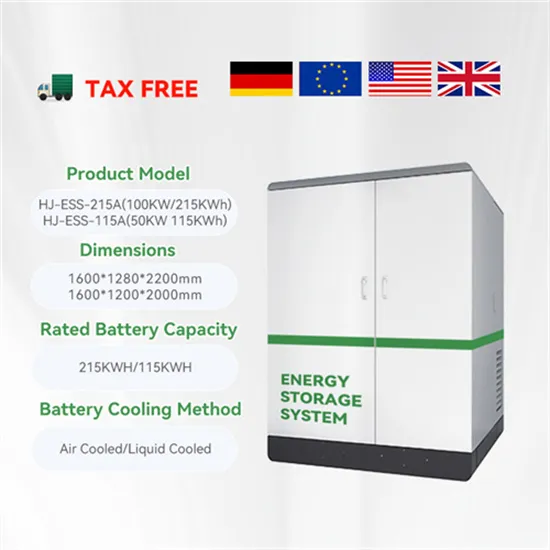

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.